Facilities and Services

Differential Scanning Calorimeter (DSC) – Netzsch 200 F3 Maia

The differential scanning calorimetry technique enables the identification of thermal transitions of a sample under heating and/or cooling, such as melting, crystallisation, glass transition, and others, and is conventionally used for polymer analysis.

Operational details:

-

Temperature: -60 °C to 400 °C

-

Atmosphere: inert (N₂) or oxidative (O₂ or synthetic air)

-

Heating rate: 10 °C/min

Thermogravimetric Analysis (TGA) – Netzsch 209 F3 Tarsus

The thermogravimetric technique measures the mass variation of a sample during a heating ramp and is commonly used to assess the thermal degradation of various materials.

Operational details:

-

Temperature: room temperature to 800 °C

-

Atmosphere: inert (N₂) or oxidative (O₂ or synthetic air)

-

Heating rate: 10 °C/min or 20 °C/min

Parallel Plate Rheometer – Anton Paar MCR 302

Parallel plate rheometry is a technique used to study the flow behaviour of a wide range of materials. Tests can be performed under oscillatory deformation (such as frequency, amplitude, or time sweeps) and/or steady state, allowing the evaluation of the samples’ complex viscosity, as well as their molar mass, loss modulus, and storage modulus.

Operational details:

-

Temperature: room temperature to 400 °C

-

Atmosphere: inert (N₂) or oxidative (atmospheric air)

-

Shear rate: 0.0001 s⁻¹ to 1000 s⁻¹

-

Frequency: 0.00001 Hz to 100 Hz

-

Angular frequency: 0.00001 rad·s⁻¹ to 600 rad·s⁻¹

Micro-Viscometer – Anton Paar AMVn

The micro-viscometer is an instrument that measures the elapsed time during the passage of the sample solution through a defined section of a capillary tube. This technique can be used to determine intrinsic viscosity, inherent viscosity, relative viscosity, specific viscosity, reduced viscosity, and the molar mass of different samples.

Operational details:

- Capillary diameter: 1,8 mm ou 1,59 mm

Goniometer – Ramé-Hart 260 F4

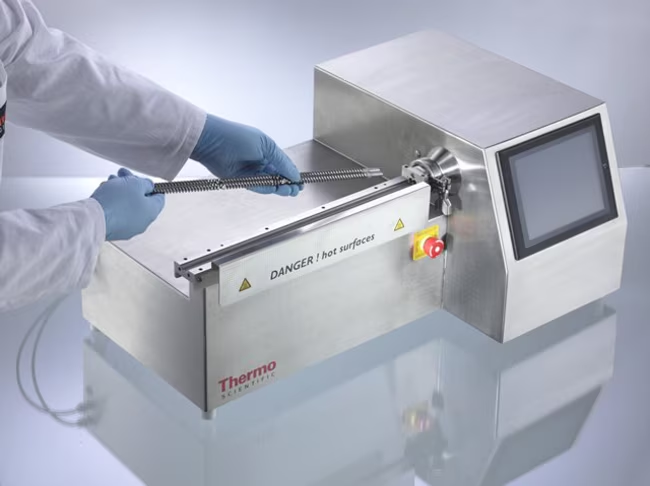

Co-Rotating Twin-Screw Extruder – Thermo Scientific Process 11 Parallel Twin-Screw Extruder

The twin-screw extruder is used for polymer and blend processing, particularly for formulation development and additive incorporation, as it offers excellent mixing capability. It is equipped with a water bath and a pelletiser, as well as two volumetric side feeders for pelletised or powdered polymers and powdered additives.

Operational details:

-

Temperature: room temperature to 350 °C

-

Screw speed: 10 to 1,000 RPM

-

Maximum pressure: 100 bar

-

Screw diameter: 11 mm

-

Barrel length: 40 L/D

Extrusora mono-rosca – Wellzoom Desktop Filament Extruder B

The single-screw extruder is used for processing polymeric materials that do not involve additive incorporation or require high mixing capacity. It can be fed with polymers in pellet or powder form.

Operational details:

-

Temperature: room temperature up to 300 °C

-

Die diameter: 1.75 mm or 3 mm

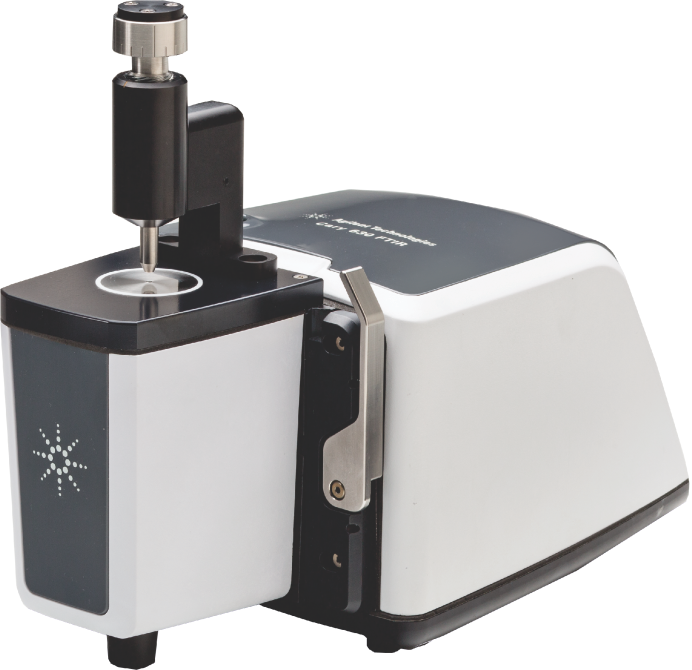

Fourier Transform Infrared Spectrometer (FTIR) – Agilent Cary 630

The FTIR technique is used to assess the chemical composition of a wide variety of materials by determining the functional groups present in the sample.

Operational details:

-

Operation mode: ATR, Transmission

-

Crystal: ZnSe

-

Spectral range: 5100 cm⁻¹ to 600 cm⁻¹

-

Sample type: solids, liquids, powders, pastes, etc.

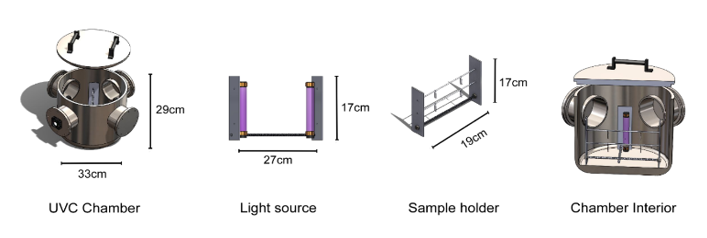

UV-C Irradiation Chamber

The UV-C irradiation chamber was built in the laboratory and is equipped with two 4 W Hg lamps emitting at 254 nm. It is used for irradiating samples to study the stability and degradation of different materials under UV-C radiation.

Operational details:

-

Emission peak: 254 nm

-

Temperature: room temperature

-

Distance between sample holder and radiation source: 13 cm

Plasma Reactor

The radiofrequency plasma reactor is equipped with a capacitively coupled parallel electrode system with an automatic matching device. It enables the addition/removal of functional groups, nanotopography modification, and film deposition.

Operational details:

-

Temperature: non-thermal plasma

-

Frequency: 13.56 MHz

-

Pressure: low pressures (0.2 to 1.5 Torr)

-

Working gases: Oxygen, Argon, Acetylene, and Carbon Dioxide

-

Gas flow: variable

-

Power: variable (30 to 100 W)

Impressora 3D

The 3D printer is used to produce parts and prototypes, allowing easy and practical adaptations. This makes it possible to meet the specific needs of each project in a customised manner.

Operational details:

-

Printing technology: Fused Filament Fabrication (FFF)

-

Temperature: room temperature to 275 °C

-

Nozzle diameter: 0.4 mm

-

Filament diameter: 1.75 mm

-

Printing speed: up to 120 mm/s

Click here to contact us and hire our services